Bouchage

in Champagne1. the process of bouchage

a. Bottle filling and dosing: After the champagne has matured in the bottle for a certain period of time, it is prepared for the final filling. At this point, a dosage, i.e. a mixture of champagne and sugar, is added. This dosage determines the final flavour of the champagne and can range from extra brut (very dry) to doux (sweet).

b. Use of the crown cork: The bottle is then sealed with a crown cap, which consists of a thin metal plate and sits on the neck of the bottle. This crown cap is pressed onto the bottle using a special machine and secured by small wires that are passed under the cork. The crown cork protects the champagne from external influences and prevents carbon dioxide from escaping.

c. The vibrating console: After bouchage, the bottles are placed on vibrating desks, which gently swing and turn them at regular intervals. This process, known as "riddling", ensures that the yeast sediments created during fermentation move towards the bottle opening. Shaking is particularly important for champagne produced using the traditional "Méthode Champenoise" method.

d. Disgorging: As soon as the yeast sediments have collected at the bottle opening, the so-called disgorging is carried out. This involves holding the neck of the bottle in an ice bucket to freeze the yeast sediment. The crown cap is then removed with a firm tug, which ejects the frozen yeast plug.

e. Final closure: After disgorging, the champagne is sealed once again with a cork that is secured with a thin wire spiral, the "muselet". This cork is larger than the crown cork and ensures that the champagne can be stored safely.

2. materials and technologies

a. The cork: Traditionally, corks are made from cork oak bark, which is known for its elasticity and ability to provide a tight seal. However, modern champagne corks can also be made from a mixture of cork and synthetic materials to ensure better consistency and durability.

b. The crown cap and the muselet: Crown corks are made of lightweight metal and are designed to withstand the pressure of the sparkling wine. The muselet, a type of wire basket, is wrapped around the cork for added security. There are many different designs and patterns of muselets, which are often used for marketing and branding purposes.

c. The filling machines: The machines that automate the bouchage process are highly sophisticated and precise. They are designed to seal a large number of bottles efficiently and consistently without compromising the quality of the champagne.

3. importance for the quality of the champagne

The bouchage process is of great importance for the quality and character of the champagne. Improperly sealed champagne can lose quality as air or other impurities can enter the bottle and spoil the sparkling wine. The correct closure ensures that the champagne retains its freshness, fine bubbles and complex flavours.

4. historical aspects

The bouchage process has undergone a long development in the history of champagne. In the past, bottles were sealed with wooden corks or even wax. It was not until the 19th century that the crown cork was introduced, which ensured a secure seal and made it easier to store and transport champagne.

5. future of the bouchage

Bouchage technology is constantly evolving. New materials and technologies are being researched to improve efficiency and reduce the impact on the environment. Efforts are being made to make the bouchage process more sustainable by using recyclable or biodegradable materials.

To summarise, the bouchage process is not only a technical necessity, but also an art form that significantly influences the end product. It is a key component in the production of champagne and contributes significantly to the quality and enjoyment of the end product.

Back to the lexicon & glossary | You were here: Bouchage

https://champagner.com/wp-content/uploads/2021/01/Jouy-les-Reims-PLZ-51390.jpeg

375

500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-22 09:12:262024-08-03 21:16:21Jouy-lès-Rheims

https://champagner.com/wp-content/uploads/2021/01/Jouy-les-Reims-PLZ-51390.jpeg

375

500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-22 09:12:262024-08-03 21:16:21Jouy-lès-Rheims champagne.com

https://champagner.com/wp-content/uploads/2018/04/BINET_Montagne_de_Reims.jpg

336

500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 18:42:182024-08-03 21:17:37Reims

champagne.com

https://champagner.com/wp-content/uploads/2018/04/BINET_Montagne_de_Reims.jpg

336

500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 18:42:182024-08-03 21:17:37Reims https://champagner.com/wp-content/uploads/2021/01/Epernay-PLZ-51200.webp

906

1360

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 18:30:232024-08-03 21:18:27Épernay

https://champagner.com/wp-content/uploads/2021/01/Epernay-PLZ-51200.webp

906

1360

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 18:30:232024-08-03 21:18:27Épernay https://champagner.com/wp-content/uploads/2021/01/INAO.jpg

675

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:56:042024-08-03 21:19:50INAO

https://champagner.com/wp-content/uploads/2021/01/INAO.jpg

675

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:56:042024-08-03 21:19:50INAO champagne.com

https://champagner.com/wp-content/uploads/2018/04/alfred-gratien.jpg

1280

1920

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:52:002024-08-03 21:22:10Historical grape varieties

champagne.com

https://champagner.com/wp-content/uploads/2018/04/alfred-gratien.jpg

1280

1920

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:52:002024-08-03 21:22:10Historical grape varieties https://champagner.com/wp-content/uploads/2021/01/hautvillers-champagne.jpg

960

1440

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:48:202024-08-03 21:23:20Hautvillers

https://champagner.com/wp-content/uploads/2021/01/hautvillers-champagne.jpg

960

1440

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:48:202024-08-03 21:23:20Hautvillers https://champagner.com/wp-content/uploads/2021/01/Haltbarkeit-und-Lagerung.jpeg

440

783

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:46:572024-08-03 21:24:14Shelf life and storage

https://champagner.com/wp-content/uploads/2021/01/Haltbarkeit-und-Lagerung.jpeg

440

783

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 16:46:572024-08-03 21:24:14Shelf life and storage https://champagner.com/wp-content/uploads/2021/01/Grauves-PLZ-51190.jpg

768

1600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 13:40:432024-08-03 21:24:57Grey vines

https://champagner.com/wp-content/uploads/2021/01/Grauves-PLZ-51190.jpg

768

1600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 13:40:432024-08-03 21:24:57Grey vines champagne.com

https://champagner.com/wp-content/uploads/2018/04/Champagner-H-Blin.jpg

1200

1600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 13:38:272024-08-03 21:28:31Champagne glasses

champagne.com

https://champagner.com/wp-content/uploads/2018/04/Champagner-H-Blin.jpg

1200

1600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 13:38:272024-08-03 21:28:31Champagne glasses https://champagner.com/wp-content/uploads/2021/01/Flaschengaerung.jpg

800

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 00:03:282024-08-03 21:33:23Bottle fermentation

https://champagner.com/wp-content/uploads/2021/01/Flaschengaerung.jpg

800

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-10 00:03:282024-08-03 21:33:23Bottle fermentation https://champagner.com/wp-content/uploads/2021/01/Flaschendruck.jpg

1125

2000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:40:192024-08-03 21:34:25Bottle pressure

https://champagner.com/wp-content/uploads/2021/01/Flaschendruck.jpg

1125

2000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:40:192024-08-03 21:34:25Bottle pressure https://champagner.com/wp-content/uploads/2021/01/Fermentation.jpg

630

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:39:482024-08-03 21:36:08Fermentation

https://champagner.com/wp-content/uploads/2021/01/Fermentation.jpg

630

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:39:482024-08-03 21:36:08Fermentation champagne.com

https://champagner.com/wp-content/uploads/2018/04/billecart-salmon-champagner-extra-brut.png

600

600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:37:402024-08-03 21:37:45Extra Brut

champagne.com

https://champagner.com/wp-content/uploads/2018/04/billecart-salmon-champagner-extra-brut.png

600

600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:37:402024-08-03 21:37:45Extra Brut https://champagner.com/wp-content/uploads/2021/01/Etrechy-PLZ-51130.jpg

1024

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:35:582024-08-03 21:38:54Étréchy

https://champagner.com/wp-content/uploads/2021/01/Etrechy-PLZ-51130.jpg

1024

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:35:582024-08-03 21:38:54Étréchy https://champagner.com/wp-content/uploads/2021/01/Ecueil-PLZ-51500.jpg

367

550

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:35:182024-08-03 21:39:37Écueil

https://champagner.com/wp-content/uploads/2021/01/Ecueil-PLZ-51500.jpg

367

550

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:35:182024-08-03 21:39:37Écueil https://champagner.com/wp-content/uploads/2021/01/Doux-Champagner.webp

550

800

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:34:152024-08-03 21:40:53Doux

https://champagner.com/wp-content/uploads/2021/01/Doux-Champagner.webp

550

800

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:34:152024-08-03 21:40:53Doux https://champagner.com/wp-content/uploads/2021/01/Dizy-PLZ-51530-scaled.jpeg

1707

2560

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:33:182024-08-03 21:41:29Dizy

https://champagner.com/wp-content/uploads/2021/01/Dizy-PLZ-51530-scaled.jpeg

1707

2560

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:33:182024-08-03 21:41:29Dizy https://champagner.com/wp-content/uploads/2021/01/Cumieres-PLZ-51480.jpg

900

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:31:292024-08-03 21:42:07Cumières

https://champagner.com/wp-content/uploads/2021/01/Cumieres-PLZ-51480.jpg

900

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:31:292024-08-03 21:42:07Cumières https://champagner.com/wp-content/uploads/2021/01/Cuis-PLZ-51530.jpg

768

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:30:592024-08-03 21:42:45Cuis

https://champagner.com/wp-content/uploads/2021/01/Cuis-PLZ-51530.jpg

768

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:30:592024-08-03 21:42:45Cuis https://champagner.com/wp-content/uploads/2021/01/Cote-des-Blancs.png

860

1300

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:28:302024-08-03 21:43:36Côte des Blancs

https://champagner.com/wp-content/uploads/2021/01/Cote-des-Blancs.png

860

1300

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

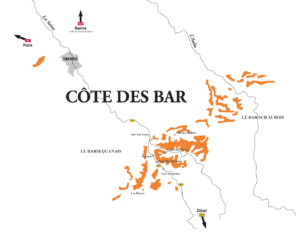

admin2021-01-09 23:28:302024-08-03 21:43:36Côte des Blancs https://champagner.com/wp-content/uploads/2021/01/Cote-des-Bar.png

1086

1407

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:27:552024-08-03 21:44:16Côte des Bar

https://champagner.com/wp-content/uploads/2021/01/Cote-des-Bar.png

1086

1407

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:27:552024-08-03 21:44:16Côte des Bar https://champagner.com/wp-content/uploads/2021/01/Coligny-PLZ-51130.jpg

1620

2160

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:26:312024-08-03 21:45:13Coligny

https://champagner.com/wp-content/uploads/2021/01/Coligny-PLZ-51130.jpg

1620

2160

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:26:312024-08-03 21:45:13Coligny https://champagner.com/wp-content/uploads/2021/01/CIVC-comite-champagne.jpg

669

892

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:25:432024-08-03 21:46:22CIVC

https://champagner.com/wp-content/uploads/2021/01/CIVC-comite-champagne.jpg

669

892

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:25:432024-08-03 21:46:22CIVC https://champagner.com/wp-content/uploads/2021/01/Chouilly-PLZ-51530.jpg

665

1000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:24:202024-08-03 21:48:38Chouilly

https://champagner.com/wp-content/uploads/2021/01/Chouilly-PLZ-51530.jpg

665

1000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:24:202024-08-03 21:48:38Chouilly https://champagner.com/wp-content/uploads/2021/01/Chlorose.jpg

491

873

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:12:392024-08-03 21:49:24Chlorosis

https://champagner.com/wp-content/uploads/2021/01/Chlorose.jpg

491

873

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:12:392024-08-03 21:49:24Chlorosis https://champagner.com/wp-content/uploads/2021/01/Chigny-les-Roses-PLZ-51500.jpg

688

917

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:09:162024-08-03 21:50:24Chigny-les-Roses

https://champagner.com/wp-content/uploads/2021/01/Chigny-les-Roses-PLZ-51500.jpg

688

917

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:09:162024-08-03 21:50:24Chigny-les-Roses https://champagner.com/wp-content/uploads/2021/01/Chaufferettes-Champagner.jpg

375

647

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:02:152024-08-03 21:54:32Chaufferettes

https://champagner.com/wp-content/uploads/2021/01/Chaufferettes-Champagner.jpg

375

647

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 23:02:152024-08-03 21:54:32Chaufferettes https://champagner.com/wp-content/uploads/2021/01/Champillon-PLZ-51160.jpg

1440

2560

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:56:322024-08-03 21:55:46Champillon

https://champagner.com/wp-content/uploads/2021/01/Champillon-PLZ-51160.jpg

1440

2560

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:56:322024-08-03 21:55:46Champillon https://champagner.com/wp-content/uploads/2024/07/Moet-Chandon-Champagner-Kuebel.webp

800

800

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:55:522024-08-03 21:56:36Champagne house

https://champagner.com/wp-content/uploads/2024/07/Moet-Chandon-Champagner-Kuebel.webp

800

800

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:55:522024-08-03 21:56:36Champagne house https://champagner.com/wp-content/uploads/2021/01/Chamery-PLZ-51500.jpg

750

1050

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:55:072024-08-03 21:57:21Chamery

https://champagner.com/wp-content/uploads/2021/01/Chamery-PLZ-51500.jpg

750

1050

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:55:072024-08-03 21:57:21Chamery https://champagner.com/wp-content/uploads/2021/01/Butte-de-Saran.jpg

600

900

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:54:462024-08-03 21:58:45Butte de Saran

https://champagner.com/wp-content/uploads/2021/01/Butte-de-Saran.jpg

600

900

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:54:462024-08-03 21:58:45Butte de Saran https://champagner.com/wp-content/uploads/2021/01/Brut-Zero.jpg

834

1800

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:53:442024-08-03 21:59:21Brut Zero

https://champagner.com/wp-content/uploads/2021/01/Brut-Zero.jpg

834

1800

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:53:442024-08-03 21:59:21Brut Zero https://champagner.com/wp-content/uploads/2021/01/Brut-Non-Dosage.jpg

550

1170

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:52:462024-08-03 22:00:41Brut Non Dosage

https://champagner.com/wp-content/uploads/2021/01/Brut-Non-Dosage.jpg

550

1170

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:52:462024-08-03 22:00:41Brut Non Dosage https://champagner.com/wp-content/uploads/2021/01/Brut-Nature.jpg

430

650

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:52:182024-08-03 22:01:25Brut Nature

https://champagner.com/wp-content/uploads/2021/01/Brut-Nature.jpg

430

650

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:52:182024-08-03 22:01:25Brut Nature https://champagner.com/wp-content/uploads/2021/01/Bouzy-PLZ-51150.jpg

683

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:51:302024-08-03 22:02:07Bouzy

https://champagner.com/wp-content/uploads/2021/01/Bouzy-PLZ-51150.jpg

683

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:51:302024-08-03 22:02:07Bouzy https://champagner.com/wp-content/uploads/2021/01/Bisseuil-PLZ-51150.jpeg

182

278

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:50:442024-08-03 22:02:44Bisseuil

https://champagner.com/wp-content/uploads/2021/01/Bisseuil-PLZ-51150.jpeg

182

278

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:50:442024-08-03 22:02:44Bisseuil https://champagner.com/wp-content/uploads/2021/01/Billy-le-Grand-PLZ-51400.jpg

853

1280

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:49:492024-08-03 22:03:24Billy-le-Grand

https://champagner.com/wp-content/uploads/2021/01/Billy-le-Grand-PLZ-51400.jpg

853

1280

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:49:492024-08-03 22:03:24Billy-le-Grand https://champagner.com/wp-content/uploads/2021/01/Bezannes-PLZ-51430.jpg

720

960

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:48:342024-08-03 22:04:02Bezannes

https://champagner.com/wp-content/uploads/2021/01/Bezannes-PLZ-51430.jpg

720

960

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:48:342024-08-03 22:04:02Bezannes https://champagner.com/wp-content/uploads/2021/01/Bergeres-les-Vertus-PLZ-51130.jpg

520

1920

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:47:452024-08-03 22:04:41Bergères-lès-Vertus

https://champagner.com/wp-content/uploads/2021/01/Bergeres-les-Vertus-PLZ-51130.jpg

520

1920

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:47:452024-08-03 22:04:41Bergères-lès-Vertus https://champagner.com/wp-content/uploads/2021/01/Beaumont-sur-Vesle-PLZ-51360.jpg

644

997

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:46:562024-08-03 22:05:29Beaumont-sur-Vesle

https://champagner.com/wp-content/uploads/2021/01/Beaumont-sur-Vesle-PLZ-51360.jpg

644

997

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:46:562024-08-03 22:05:29Beaumont-sur-Vesle champagne.com

https://champagner.com/wp-content/uploads/2018/05/catter-champagner-blanc-de-noir.jpg

402

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:46:022024-08-03 22:07:33BdN

champagne.com

https://champagner.com/wp-content/uploads/2018/05/catter-champagner-blanc-de-noir.jpg

402

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:46:022024-08-03 22:07:33BdN https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:45:302024-08-03 22:08:25BdB

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:45:302024-08-03 22:08:25BdB https://champagner.com/wp-content/uploads/2021/01/Ay-PLZ-51160.jpg

900

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:44:202024-11-04 13:07:13Ay

https://champagner.com/wp-content/uploads/2021/01/Ay-PLZ-51160.jpg

900

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:44:202024-11-04 13:07:13Ay https://champagner.com/wp-content/uploads/2021/01/Avize-PLZ-51190.webp

375

500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:42:592024-08-03 22:09:42Avize

https://champagner.com/wp-content/uploads/2021/01/Avize-PLZ-51190.webp

375

500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:42:592024-08-03 22:09:42Avize https://champagner.com/wp-content/uploads/2021/01/Avenay-PLZ-51160.jpg

499

752

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:42:262024-08-03 22:10:29Avenay

https://champagner.com/wp-content/uploads/2021/01/Avenay-PLZ-51160.jpg

499

752

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:42:262024-08-03 22:10:29Avenay https://champagner.com/wp-content/uploads/2021/01/Autochthon-Champagner.jpg

1080

1920

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:41:442024-11-04 13:04:05Autochthonous

https://champagner.com/wp-content/uploads/2021/01/Autochthon-Champagner.jpg

1080

1920

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:41:442024-11-04 13:04:05Autochthonous https://champagner.com/wp-content/uploads/2024/07/Weinreben-Champagne.png

593

898

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:40:182024-11-04 12:59:36Arbane

https://champagner.com/wp-content/uploads/2024/07/Weinreben-Champagne.png

593

898

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:40:182024-11-04 12:59:36Arbane https://champagner.com/wp-content/uploads/2021/01/Ambonnay-PLZ-51150.webp

450

600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:38:102024-11-04 12:56:59Ambonnay

https://champagner.com/wp-content/uploads/2021/01/Ambonnay-PLZ-51150.webp

450

600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:38:102024-11-04 12:56:59Ambonnay https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:37:022024-11-04 12:54:00Astringency

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:37:022024-11-04 12:54:00Astringency https://champagner.com/wp-content/uploads/2021/01/A-la-volée.jpg

900

1600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:36:282024-08-03 22:12:33A la volée

https://champagner.com/wp-content/uploads/2021/01/A-la-volée.jpg

900

1600

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:36:282024-08-03 22:12:33A la volée champagne.com

https://champagner.com/wp-content/uploads/2018/04/champagner-schauer.jpg

900

1500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:35:482024-11-04 12:51:44Dégorgement à la Glace

champagne.com

https://champagner.com/wp-content/uploads/2018/04/champagner-schauer.jpg

900

1500

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:35:482024-11-04 12:51:44Dégorgement à la Glace https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:34:422024-08-03 22:14:22Champagne bottles

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:34:422024-08-03 22:14:22Champagne bottles https://champagner.com/wp-content/uploads/2021/01/champagner-korken.jpg

787

1181

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:25:422024-08-03 22:15:15Cork

https://champagner.com/wp-content/uploads/2021/01/champagner-korken.jpg

787

1181

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:25:422024-08-03 22:15:15Cork https://champagner.com/wp-content/uploads/2021/01/Viticulture.jpg

1707

2560

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:24:032024-08-03 22:15:56Viticulture

https://champagner.com/wp-content/uploads/2021/01/Viticulture.jpg

1707

2560

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:24:032024-08-03 22:15:56Viticulture https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:23:312024-08-03 22:16:35Viniculture

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:23:312024-08-03 22:16:35Viniculture https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:22:362024-08-03 22:17:47Vin Gris

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:22:362024-08-03 22:17:47Vin Gris https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:22:052024-08-03 22:18:23Vignoble

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:22:052024-08-03 22:18:23Vignoble https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:13:582024-08-03 22:18:54Vigne

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:13:582024-08-03 22:18:54Vigne https://champagner.com/wp-content/uploads/2021/01/Vieilles-Vigne.jpg

638

850

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:12:422024-08-03 22:19:29Vieilles Vignes

https://champagner.com/wp-content/uploads/2021/01/Vieilles-Vigne.jpg

638

850

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:12:422024-08-03 22:19:29Vieilles Vignes https://champagner.com/wp-content/uploads/2024/07/Veuve-Clicquot-1950.jpg

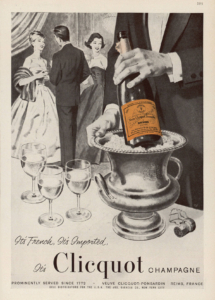

1674

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:11:442024-08-03 22:20:57Veuve Clicquot

https://champagner.com/wp-content/uploads/2024/07/Veuve-Clicquot-1950.jpg

1674

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:11:442024-08-03 22:20:57Veuve Clicquot https://champagner.com/wp-content/uploads/2024/07/Ferdinand-Bonnet-Champagner-Weinlese.webp

1298

1304

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:10:312024-08-03 22:21:39Vendange

https://champagner.com/wp-content/uploads/2024/07/Ferdinand-Bonnet-Champagner-Weinlese.webp

1298

1304

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:10:312024-08-03 22:21:39Vendange https://champagner.com/wp-content/uploads/2021/01/Traubensorten-Champagner.jpeg

453

893

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:09:592024-08-03 07:17:50Grape varieties

https://champagner.com/wp-content/uploads/2021/01/Traubensorten-Champagner.jpeg

453

893

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:09:592024-08-03 07:17:50Grape varieties https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:09:052024-08-03 22:22:26Terroir

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:09:052024-08-03 22:22:26Terroir https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:08:252024-08-03 07:08:09Tannin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:08:252024-08-03 07:08:09Tannin https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:07:392024-08-03 22:23:20Waist

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:07:392024-08-03 22:23:20Waist https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:06:562024-08-03 07:04:23Tâché

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:06:562024-08-03 07:04:23Tâché https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:06:172024-08-03 07:02:14Sparkling wine

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:06:172024-08-03 07:02:14Sparkling wine https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:05:402024-08-03 22:24:52Sec

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:05:402024-08-03 22:24:52Sec https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:05:032024-08-03 22:25:27Ship christening

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:05:032024-08-03 22:25:27Ship christening https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:01:372024-08-03 22:32:00Prosecco

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:01:372024-08-03 22:32:00Prosecco https://champagner.com/wp-content/uploads/2021/01/Asti-Spumante.jpg

408

1300

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:01:002024-11-04 13:01:26Asti Spumante

https://champagner.com/wp-content/uploads/2021/01/Asti-Spumante.jpg

408

1300

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 22:01:002024-11-04 13:01:26Asti Spumante https://champagner.com/wp-content/uploads/2021/01/schaumwein.jpg

809

1440

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:59:092024-08-03 22:35:14Sparkling wine

https://champagner.com/wp-content/uploads/2021/01/schaumwein.jpg

809

1440

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:59:092024-08-03 22:35:14Sparkling wine https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:58:032024-08-03 22:39:34Acid

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:58:032024-08-03 22:39:34Acid https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:57:232024-08-03 22:41:08Sans-année

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:57:232024-08-03 22:41:08Sans-année https://champagner.com/wp-content/uploads/2021/01/Saint-Evremond.jpg

512

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:56:482024-08-03 02:30:20Saint-Evremond

https://champagner.com/wp-content/uploads/2021/01/Saint-Evremond.jpg

512

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:56:482024-08-03 02:30:20Saint-Evremond https://champagner.com/wp-content/uploads/2021/01/gyropalette.webp

347

576

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:56:022024-08-03 01:43:33Vibrating desk

https://champagner.com/wp-content/uploads/2021/01/gyropalette.webp

347

576

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:56:022024-08-03 01:43:33Vibrating desk https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:54:082024-08-03 01:32:17Shake

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:54:082024-08-03 01:32:17Shake https://champagner.com/wp-content/uploads/2024/07/Ruinart-Champagner.jpg

630

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:53:082024-08-03 01:07:39Ruinart

https://champagner.com/wp-content/uploads/2024/07/Ruinart-Champagner.jpg

630

1200

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:53:082024-08-03 01:07:39Ruinart https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:52:162024-08-03 01:05:23Rosé des Riceys

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:52:162024-08-03 01:05:23Rosé des Riceys champagne.com

https://champagner.com/wp-content/uploads/2018/04/besserat-de-bellefon-champagner-rose.jpg

1081

1812

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:51:352024-08-03 01:03:32Rosé

champagne.com

https://champagner.com/wp-content/uploads/2018/04/besserat-de-bellefon-champagner-rose.jpg

1081

1812

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:51:352024-08-03 01:03:32Rosé https://champagner.com/wp-content/uploads/2021/01/louis-roederer.jpg

447

1440

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:50:302024-08-03 01:01:51Roederer

https://champagner.com/wp-content/uploads/2021/01/louis-roederer.jpg

447

1440

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:50:302024-08-03 01:01:51Roederer https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:49:552024-08-03 00:58:57Residual sugar

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:49:552024-08-03 00:58:57Residual sugar https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:49:102024-08-03 00:39:59Remueur

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:49:102024-08-03 00:39:59Remueur https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:48:302024-08-03 00:38:14Réduction François

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:48:302024-08-03 00:38:14Réduction François https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:47:512024-08-03 00:36:10Récoltant-Manipulant (R.M.)

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:47:512024-08-03 00:36:10Récoltant-Manipulant (R.M.) https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:47:152024-08-03 00:20:47Récolte

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:47:152024-08-03 00:20:47Récolte https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:46:222024-08-03 00:19:27Phylloxera

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:46:222024-08-03 00:19:27Phylloxera https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:45:162024-08-03 00:17:41Rebêche

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:45:162024-08-03 00:17:41Rebêche https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:44:042024-08-03 00:15:58Ratafia de Champagne

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:44:042024-08-03 00:15:58Ratafia de Champagne https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:42:382024-08-03 00:14:18Rappen

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:42:382024-08-03 00:14:18Rappen https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:41:332024-08-03 00:12:33Pressoir

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:41:332024-08-03 00:12:33Pressoir champagne.com

https://champagner.com/wp-content/uploads/2021/01/domaine-pommery.jpg

760

1360

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:40:272024-08-03 00:11:00Pommery

champagne.com

https://champagner.com/wp-content/uploads/2021/01/domaine-pommery.jpg

760

1360

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:40:272024-08-03 00:11:00Pommery champagne.com

https://champagner.com/wp-content/uploads/2021/01/coulournat-gilles-champagne.png

700

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:39:232024-08-03 00:09:16Placomusophilia

champagne.com

https://champagner.com/wp-content/uploads/2021/01/coulournat-gilles-champagne.png

700

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:39:232024-08-03 00:09:16Placomusophilia https://champagner.com/wp-content/uploads/2021/01/Capsules-Muselets-Plaque-Champagner-Deckel.jpg

462

960

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:37:312024-08-03 00:07:34Plaque

https://champagner.com/wp-content/uploads/2021/01/Capsules-Muselets-Plaque-Champagner-Deckel.jpg

462

960

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:37:312024-08-03 00:07:34Plaque champagne.com

https://champagner.com/wp-content/uploads/2018/05/canard-duchene-champagner-pinot-noir.jpg

514

570

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:36:412024-08-03 00:06:26Pinot Noir

champagne.com

https://champagner.com/wp-content/uploads/2018/05/canard-duchene-champagner-pinot-noir.jpg

514

570

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:36:412024-08-03 00:06:26Pinot Noir https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:35:442024-08-03 00:03:53Pinot Meunier

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:35:442024-08-03 00:03:53Pinot Meunier https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:35:062024-08-03 00:01:58Pinot Gris

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:35:062024-08-03 00:01:58Pinot Gris https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:34:052024-08-02 23:58:02Pétillant

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:34:052024-08-02 23:58:02Pétillant https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:32:582024-08-02 23:54:36Perlant

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:32:582024-08-02 23:54:36Perlant https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:30:062024-08-02 23:53:04Oxidation

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:30:062024-08-02 23:53:04Oxidation https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:29:372024-08-02 23:51:15Oxhoft

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:29:372024-08-02 23:51:15Oxhoft https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:28:452024-08-02 23:49:26Ouverture des Vendanges

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:28:452024-08-02 23:49:26Ouverture des Vendanges https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:28:082024-08-02 23:43:48Oenology

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:28:082024-08-02 23:43:48Oenology https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:26:362024-08-02 23:42:34Öchsle

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:26:362024-08-02 23:42:34Öchsle https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:25:192024-08-02 23:40:34Négociant

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:25:192024-08-02 23:40:34Négociant https://champagner.com/wp-content/uploads/2021/01/Nase-Champagner.jpeg

1125

2000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:24:322024-08-03 01:45:19Nose

https://champagner.com/wp-content/uploads/2021/01/Nase-Champagner.jpeg

1125

2000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:24:322024-08-03 01:45:19Nose https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:23:042024-08-02 23:34:13N.V.

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:23:042024-08-02 23:34:13N.V. https://champagner.com/wp-content/uploads/2021/01/Agraffe.jpg

600

900

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:21:572024-08-02 23:24:29Muselet

https://champagner.com/wp-content/uploads/2021/01/Agraffe.jpg

600

900

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:21:572024-08-02 23:24:29Muselet https://champagner.com/wp-content/uploads/2024/07/Mumm-Champagne.jpg

1080

1080

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:16:082024-08-03 06:21:54Guts

https://champagner.com/wp-content/uploads/2024/07/Mumm-Champagne.jpg

1080

1080

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:16:082024-08-03 06:21:54Guts https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:12:532024-08-03 06:18:34Moût

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:12:532024-08-03 06:18:34Moût https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:12:092024-08-03 06:16:56Mousseux

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:12:092024-08-03 06:16:56Mousseux https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:11:112024-08-03 06:17:51Mousse

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:11:112024-08-03 06:17:51Mousse https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:10:222024-08-03 06:23:34Mono-Cru

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 21:10:222024-08-03 06:23:34Mono-Cru https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:52:522024-08-03 06:24:42Méthode Champenoise

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:52:522024-08-03 06:24:42Méthode Champenoise https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:51:542024-08-03 06:25:34Marc

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:51:542024-08-03 06:25:34Marc https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:51:142024-08-03 06:26:28Maie

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:51:142024-08-03 06:26:28Maie https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:50:222024-08-03 06:28:08Malolactic fermentation

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:50:222024-08-03 06:28:08Malolactic fermentation https://champagner.com/wp-content/uploads/2021/01/Maceration.jpg

667

1000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:49:422024-08-03 06:32:21Maceration

https://champagner.com/wp-content/uploads/2021/01/Maceration.jpg

667

1000

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:49:422024-08-03 06:32:21Maceration https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:49:092024-08-03 06:33:53Long

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:49:092024-08-03 06:33:53Long champagner.eu

https://champagner.com/wp-content/uploads/2021/01/Liqueur-de-tirage.jpg

334

750

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:48:332024-08-01 03:10:50Liqueur de tirage

champagner.eu

https://champagner.com/wp-content/uploads/2021/01/Liqueur-de-tirage.jpg

334

750

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:48:332024-08-01 03:10:50Liqueur de tirage https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:47:302024-08-03 06:34:55Liqueur d'expédition

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:47:302024-08-03 06:34:55Liqueur d'expédition https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:45:312024-08-03 06:35:56Read

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:45:312024-08-03 06:35:56Read champagne.com

https://champagner.com/wp-content/uploads/2021/01/KRUG-CHAMPAGNE.png

350

350

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:43:552024-08-01 03:08:43Krug

champagne.com

https://champagner.com/wp-content/uploads/2021/01/KRUG-CHAMPAGNE.png

350

350

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:43:552024-08-01 03:08:43Krug https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:42:242024-08-03 06:37:45Body

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:42:242024-08-03 06:37:45Body https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:41:462024-08-03 06:38:42Cork flavour

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:41:462024-08-03 06:38:42Cork flavour https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:40:272024-08-03 06:39:40Carbon dioxide

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:40:272024-08-03 06:39:40Carbon dioxide https://champagner.com/wp-content/uploads/2021/01/Kirchenfenster-Champagner.webp

430

430

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:39:302024-08-03 08:04:14Church windows

https://champagner.com/wp-content/uploads/2021/01/Kirchenfenster-Champagner.webp

430

430

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:39:302024-08-03 08:04:14Church windows https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:38:222024-08-03 06:40:30Pressing

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-09 20:38:222024-08-03 06:40:30Pressing champagne.com

https://champagner.com/wp-content/uploads/2021/01/ruinart-champagne.png

700

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:37:072024-08-03 07:01:13Champagne capsule

champagne.com

https://champagner.com/wp-content/uploads/2021/01/ruinart-champagne.png

700

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:37:072024-08-03 07:01:13Champagne capsule https://champagner.com/wp-content/uploads/2021/01/Jahrgangschampagner.webp

538

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:34:592024-08-01 03:01:09Vintage champagne

https://champagner.com/wp-content/uploads/2021/01/Jahrgangschampagner.webp

538

1024

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:34:592024-08-01 03:01:09Vintage champagne https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:33:352024-08-03 06:41:51Wood

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:33:352024-08-03 06:41:51Wood https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:32:402024-08-03 06:42:50Heidsieck

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:32:402024-08-03 06:42:50Heidsieck https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:31:362024-08-03 06:43:55Habillage

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:31:362024-08-03 06:43:55Habillage https://champagner.com/wp-content/uploads/2021/01/gyropalette.webp

347

576

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:31:002024-08-03 06:45:26Gyro palette

https://champagner.com/wp-content/uploads/2021/01/gyropalette.webp

347

576

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:31:002024-08-03 06:45:26Gyro palette https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:30:232024-08-03 06:46:27Grappillage

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:30:232024-08-03 06:46:27Grappillage https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:29:162024-08-03 06:59:45Grand Vin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:29:162024-08-03 06:59:45Grand Vin champagne.com

https://champagner.com/wp-content/uploads/2021/01/grande-reserve-gosset-champagne.png

700

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:06:452024-08-03 06:57:56Gosset

champagne.com

https://champagner.com/wp-content/uploads/2021/01/grande-reserve-gosset-champagne.png

700

700

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:06:452024-08-03 06:57:56Gosset https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:05:432024-08-03 06:55:54Brother Jean Oudart

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:05:432024-08-03 06:55:54Brother Jean Oudart https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:02:392024-08-03 06:52:56Frais

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:02:392024-08-03 06:52:56Frais https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:02:012024-08-03 06:51:47Foudre

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:02:012024-08-03 06:51:47Foudre https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:01:112024-08-03 06:50:54Firn

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:01:112024-08-03 06:50:54Firn https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:00:372024-08-03 06:49:52Ficeleur

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 22:00:372024-08-03 06:49:52Ficeleur https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 21:59:462024-08-03 06:48:49Extract

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 21:59:462024-08-03 06:48:49Extract https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 21:58:472024-08-03 06:47:51Épluchage

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 21:58:472024-08-03 06:47:51Épluchage https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

0

0

admin

https://champagner.com/wp-content/uploads/2024/07/Champagner.com-Logo-300x300.png

admin2021-01-08 21:57:132024-08-03 06:14:34Yeast removal